Our Photo Chemical Etching Process Guide was generated for those new to the photo chemical etching process with the hope it will serve as an industry reference and raise awareness of our etching capabilities. VACCO encourages you to utilize these tools and information when developing your next prototype requirements. If you have any questions, please feel free to contact our Sales Team for personal assistance in your design requirements.

See examples of our photochemical etching work.

Advantages of Photo Chemical Etching

As complex or challenging as your design may seem, VACCO’s photo chemical etching process makes producing intricate parts effortless. Photo Chemical Etching is a fast and relatively inexpensive way to produce a wide variety of metal parts, with continuous accuracy VACCO’s consistency is possible with our tooling capabilities. VACCO’s photo tools are digitally generated and can be imaged with LDI (Laser Direct Imaging) which increases accuracy while reducing tooling costs, in comparison to the competition that uses hard tooling.

Watch the Photo Chemical Etching Process video to see how it works.

Dimensions & Tolerances

There are no specific ground rules regarding photochemical etching tolerances however, there are some variables which can have an impact on maintaining etching tolerances. Consider the following when developing prototype specifications:

- The type of specified metal material.

- The thickness of the specified material.

- The physical size of the parts’ and its desired features.

- The process sheet size and the number of critical part dimensions.

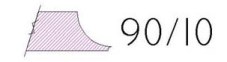

Generally speaking, photo chemical etched dimensional tolerances are ±10% of the metal thickness. If a part is made of 0.010″ thick stainless steel, then the general rule is that the dimensional tolerance of the parts’ features is ± 0.001″ (or 10% of the material thickness.)

For more information please don’t hesitate to call the VACCO Sales Engineering Team.

Hole Size/ Slot Width to Metal Thickness

Typically, the diameter of a hole or slot width can’t be less than 1.1 times the material thickness. However, the relationship varies when metal thicknesses changes. Below is a chart gives an explanation of the relationship between the hole size to metal thickness. Metal Thickness (t) Smallest Hole Diameter (d) Less than .001″ TBD by test run .001″ – .006″ At least Metal Thickness .006″ or Over At least 110% Metal Thickness

Line Width to Metal Thickness

Spacing between holes and slots becomes a design factor when a part contains a large number of holes and/or slots. The metal between the holes is referred to as “Bar Width.” There are limitations as to how small the bar width between holes can be. In metals less than .005″ thick, bar widths typically are equal to the metal thickness, but can be as narrow as the half to the metal thickness.

Inside & Outside Corner Radius to Metal Thickness

The smallest corner radius is proportional to the metal thickness. However, there are circumstances where the radius can be smaller, depending on the requirements.

Outside corners etch sharper than inside, so radii less than material thickness are easily obtainable.

Bevel

If etching variance is a requirement, please specify the percentages needed at the time of order.

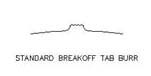

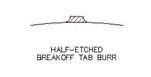

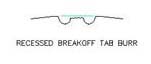

Tabs or Tie-Ins

In the photochemical etching process, tabbing is performed by connecting one or more lines of metal from the part to the process sheet border or tie bars to keep parts in place. These tie-ins are made as few and as small as possible keeping consistent with the size of the parts being etched. Tabs are beneficial for parts with tighter tolerances, and those undergoing plating operations, not to mention they are cost efficient and will help produce a higher yield of quality product. Two common variations of tabbing most widely used include:

External Tab – These have a break off point, which leaves a small “burr” attached to the part.

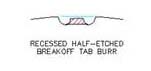

Recessed Tab – Like external tabs, recessed tabs have a breaking point, only it becomes recessed into the actual part. VACCO recommend this application if the product specifications require tabbing, but cannot have extended areas beyond its perimeter.

If outside requirements are crucial or the preference is to avoid tabbing all together, then consider drop outs. These are tab free parts, meaning the part does not remain in the sheet during the etching process. This method is recommended for metals with a thickness of .010″ or thicker. Be advised, a drop out is less consistent, has looser tolerances and therefore is more expensive to handle, inspect and package in comparison to a tabbed part.

METALS OFFERED

- Blue Tempered Spring Steel

- Brass, Alloy 230, Red

- Brass, Alloy 240

- Brass, Alloy 260, Cartridge

- Brass, Alloy 268, Yellow

- Carbon Steel, C1008,C1010

- Copper, ETP C110

- Copper, Olin 194

- Copper, OFE, OF C101, C102

- Cupro Nickel (CuNi70/30) Alloy 715

- Beryllium Copper Alloy 25, C172

- Beryllium Nickel Alloy 360

- Hafnium

- Haynes 25

- Haynes 214

- Hastelloy 276

- Hastelloy B-2

- Hastelloy X

- HyMu 80, Hypernom

- Inconel, Alloy 600/601

- Inconel, Alloy 718/X-750

- Invar

- Jeweler’s Bronze, Alloy 226

- Kovar

- L-605

- Nickel, Alloy 42, 49

- Nickel, Alloy 200/201

- Nickel, Silver, Alloy 752, 770

- Nitronic 60

- Phosphor Bronze, Alloy 510

- Sandvik

- Stainless Steel, 300 Series

- Stainless Steel, 400 Series

- Stainless Steel, 17-7PH Series

- Stainless Steel, AM-350

- Tantalum

- Titanium, CP Grades 1-4

- Titanium, Alloy 3AL-2.5V

- Titanium, Alloy 6AL-4V

- Zirconium