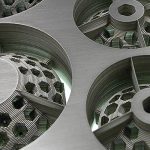

VACCO is a leader in metal diffusion bonding with over 60 years of diverse experience. Metal diffusion bonding is most suitable in applications where two similar metals need to be joined. This method is widely used for production of thin-metal components and parts with very complex shapes.

What is Diffusion Bonding?

Diffusion bonding, is a technique used in metalworking to join metals through the concept of solid-state diffusion, which is the movement of atoms or molecules from an area of high concentration to an area of low concentration. The key component of diffusion bonding is the application of pressure to two metal surfaces under high temperature that accelerates the process. The surfaces of the two metals must be smooth and free of debris for the process to be successful. Metals joined by diffusion bonding are of high quality and clean without porosity or discontinuity. The unique nature of diffusion bonding allows for the joining of similar or dissimilar metals to form a perfect and tight union.

Benefits of Diffusion Bonding

In the diffusion bonding process, two metals are permanently joined without liquid fusion, filler metals, or loss of weight. The two united metals can be of varying thicknesses but, once joined, still retain their initial strength and temperature resistance. The only limitation to the process is the amount of required pressure and various physical limitations. A major benefit of diffusion bonding is its ability to join similar metals of different thicknesses, and designs to create 3D parts with designs and or flow paths that cannot be machined using conventional methods.

Diffusion Bonding Capabilities

VACCO’s capabilities also include diffusion bonding of titanium, a metal that is valued in industrial applications for its strength and corrosion-resistant properties. VACCO’s in-house vacuum furnace enables diffusion bonding of components consisting of titanium, without deformation or residual stress.

All metal diffusion bonding projects are calculated for exact pressure measurements to consider material parameters such as surface finish, flatness, thickness, and hermetic seal requirements. Our expert team at VACCO understands the importance of controlling all process variables to produce accurate and strong metal bonds.

Whether you are seeking to increase strengths, improve flow controls, create a decorative appearance, or make electrical connections by joining materials, VACCO’s Precision Etched Parts group is equipped with an in-house vacuum furnace to handle your bonding needs. The vacuum furnace consists of a 12″ wide x 12″ high x 12″ deep hot zone capable of handling temperatures up to 1315 ºC.

Diffusion Bonding Uses

VACCO’s photo etching and diffusion bonding processes are widely used in the production of sensor devices, cooling devices, fuel cells, sound suppression devices, and micro fluid channeling devices. Parts with thicknesses that range from 0.001″ through 1″, manufactured from a variety of materials, including titanium and iron-nickel alloy, can be joined using our diffusion bonding process. VACCO uses ceramic or molybdenum material to make fixtures.

VACCO’s Engineering team calculates the right amount of pressure that should be applied to bond materials taking into consideration several parameters, including surface finish, flatness, thickness, and hermetic seal requirements. Accurately controlling process variables ensures that the strength and ductility of the joint matches that of the materials being bonded. Micro laser machining capabilities allow diffusion bond components through welding, small hole drilling, and cutting. In-house welding and liquid penetrant inspection processes comply with the PRI (Performance Review Institute) / NADCAP (National Aerospace and Defense Contractors Accreditation Program) standards. Contact us today for more information.

DIFFUSION BONDING CAPABILITIES

Primary Services

- Adhesive Bonding

- Diffusion Bonding

- Laser Micro Machining

- Photo Etching

Other Metal Joining Methods

- Brazing

- Coil-to-Coil Lamination

- Laser Welding

- Resistant Welding

- TIG Welding Soldering

Typical Materials

- Titanium

- Iron-Nickel Alloys

Fixture Materials

- Ceramic

- Molybdenum

Thickness Range

0.001″ through 1″

Hot Zone Size

12″ x 12″ x 12″

Maximum Temperature

1315º C

Positioning Accuracy

+/- 0.002″

Hermetic Sealing Parameters

- Flatness

- Pressure

- Surface Finish

- Thickness

Value-added Services

- Embossing Heat Treating

- Kiss Cutting

- Marking Special Packaging

- Plating

- Welding

- Assembly

- Bonding

Applications

- Filtration Elements

- Fluid Mixing Valves

- Fuel Cells Medical Devices

- Micro-Fluidics

- Miniature Heat Exchanges

- Others

- Scientific Controls

Industries Served

- Automotive

- Avionic/Space

- Electronic Fiber

- Mechanical/

Manufacturing - Medical

- Printers

- Scientific Controls

Certifications

- Clean Room Accredited to FED-STD-209 Class 10,000 Standards

- PRI / NADCAP Certified