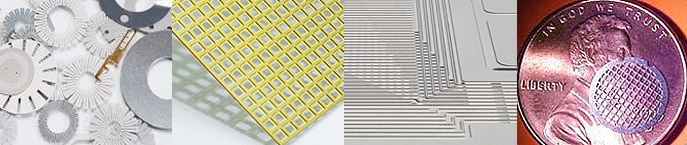

We design and manufacture photo etched components from various metals suitable for aerospace, defense, medical, electronic, filtration, automotive and many other commercial markets. Our core competency lies in producing micro-machined components, such as micro fluidic devices, screens and meshes, fuel valves, manifolds, electronic components and disc filters. Chemically Etched Miniature Systems (ChEMS ®) as well as our PhotoPore® screens are two of our patented etched products which are used in critical spacecraft and medical applications.

Types of Metals We Etch

Stainless steel

Titanium

Brass

Copper

Nickel alloy

Carbon & spring steel

HyMu

Metal Photo Etching Process

Depending on the dimensions, tolerances, edge profiles, and configuration requirements, certain materials may be better suited for your needs. Our assistance is offered upon material selection. Photo etched components can be produced from panels up to 28” x 68” in size in our clean rooms, holding minimum dimensional tolerances of ±0.0005″ and even better positional tolerances. Based on your application requirements, we can process etched components in tabbed or untabbed process sheets. Our operations yield consistent etching results and dimensional consistencies across the entire panel.

At the beginning of every fabrication project, component specifications provided by customers are reviewed thoroughly and a project engineer is assigned to each job. Design assistance is also offered to customers with Autodesk Inventor, COSMOS and Ansoft Maxwell 2D. Photographic artworks are generated according to customers’ exact specifications and are laser plotted to engineered “photo tools”. The images produced by these photo tools are exposed onto resistant dry or wet films; controlled UV exposure ensures accurate transfer of images from artwork photo tools to the process panels. As one of the largest commercial etching facilities in the United States, we offer development, prototyping and high volume manufacturing capabilities.

Statistical Process Control (SPC) is used throughout our production process and chemical controls. Our SPC ensures high quality regulation of your photo etched component. Proprietary resist removal solutions are used for stripping the resistant films from etched panels. Along with our photo etching expertise, we provide many other in-house capabilities including; Automated Visual Inspection, Assembling, Testing, Diffusion and Adhesive Bonding, Forming, Special Packaging and other value added operations performed to your components, in a dust-controlled environment. As an environmentally committed organization, we recycle all acid and metal waste.

Precision Metal Photo Etching Capabilities

Primary Services

- Photo Etching

- Adhesive Bonding

- Diffusion Bonding

- Micro Laser Cutting

- Electroforming

Specialty Processes

- Differential Etching

- Microfluidics channels

- Clean Room Assembly and Packaging

Material List

Please visit Photo Chemical Etching Process for more information.

Part Thickness

0.0005″ to 0.125″

Minimum Dimensional Tolerance

±0.0005″

Maximum Panel Size

28″ x 68″

Tab Configurations

- “V” Shaped Tabs

- Straight Tabs

Laser Micro Machining Capabilities

- Drilling

- Laser Welding

- Metal Cutting

Laser Center

- Accuracy : +/- 1 micrometer

- Repeatability: +/- 0.5 micrometer

- Rotary stage capable of 6 arc second resolution and 15 arc second accuracy

Metal Cutting

- Material Thickness: 0.001″ to 0.075″

- Rotary Tube Cutting Dimensions: 10″ in length x 1.5″ diameter

- Smallest Kerf Width on Thin Gauge Material: 0.0025″

- X – Y Travel: 18″ x 18″

Laser Welding

- Deep penetration, 90% overlap hermetic pulse seal welding

- Spot welding as small as .005″

Drilling

- 10:1 hole-to-material

- Thickness ratio capability

Value-added Services

- Embossing

- Heat Treating

- Kiss Cutting

- Marking Special Packaging

- Plating

- Welding

- Assembly

- Bonding

Applications

- Air Bag Sensors

- Carrier Screens

- Electronics Connectors

- EMI/RFI Shielding

- Encoders

- Extruding Die

- Screens

- Faraday Shielding Filtration

- Fluid Channels

- Fluid Controls

- Fuel Cells

- Haptics for Intraocular Lens

- Hearing Aid Devices

- Heat Exchangers

- Implantables LancetsMass

- Spectrometer

- Mesh & Sieving

- Orifices

- Pin Holes (leak test, pressure, etc)

- Positional Devices

- Printing Masks

- Reconstructive Mesh

- Sensor Components

- Sensors

- Shims

- Spacers/Shims

- Springs

- Stators & Rotors

- Stencils/Masks

- Support Mesh/Screen

- Switches

- Targeting/Sights/ Positionals

Industries Served

- Automotive

- Avionic / Space

- Electroni

- cFiber

- Mechanical / Manufacturing

- Medica

- Printers Scientific Controls

Certifications

- Clean Room Accredited to FED-STD-209 Class 10,000 Standards

- PRI / NADCAP Certified

Software Used

- Autodesk Inventor

- AutoCAD

Acceptable File Formats

- DWGDXFIGES

- JPEG